-

Headquarters / Mechanical

- Tel. +82-53-615-4901

- FAX. +82-53-615-4901

-

SHOTBALL

- Tel. +82-53-615-4901

- FAX. +82-53-615-2119

COPYRIGHT (C) KOREA SINTO CO,.LTD ALL RIGHTS RESERVED

COPYRIGHT (C) KOREA SINTO CO,.LTD ALL RIGHTS RESERVED

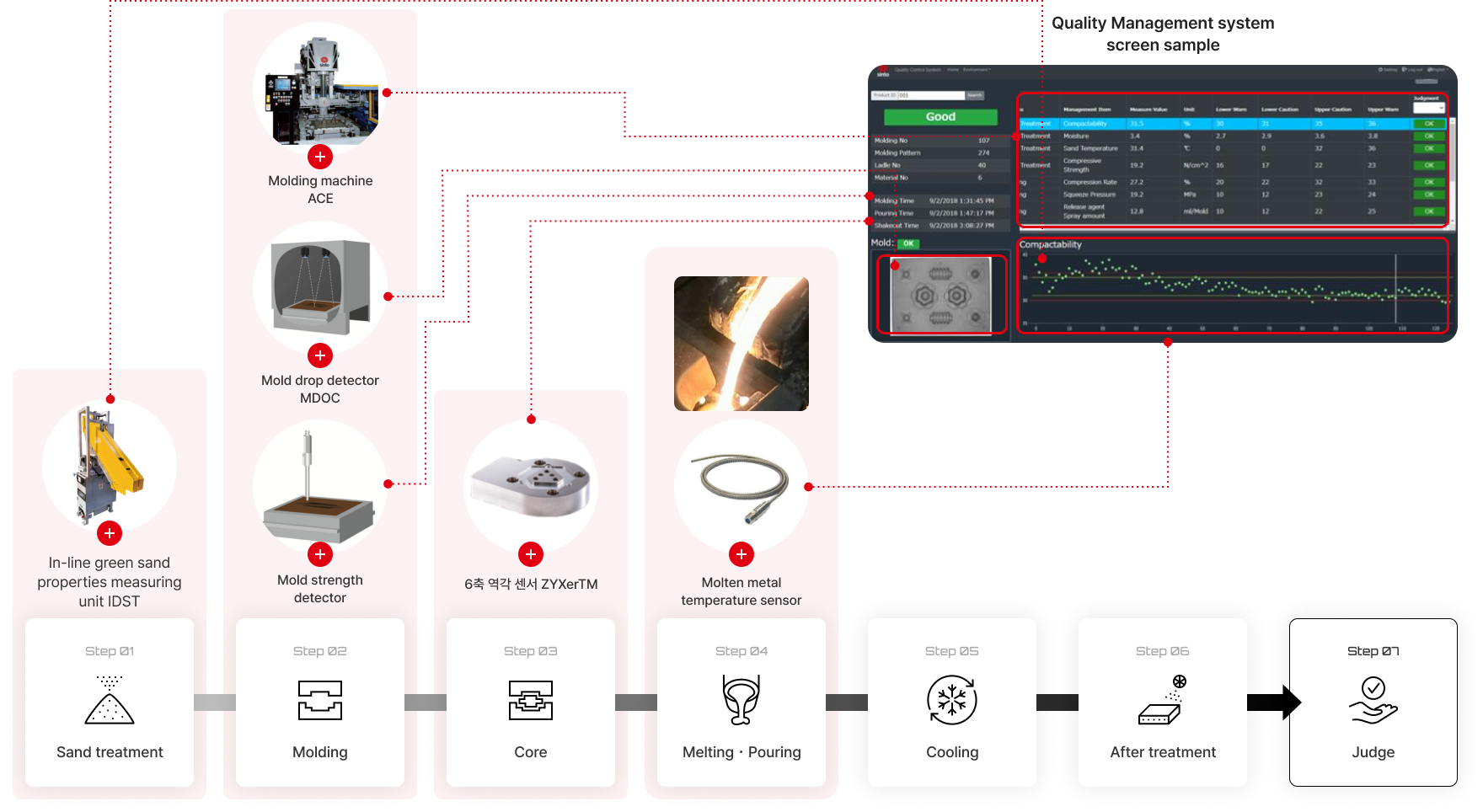

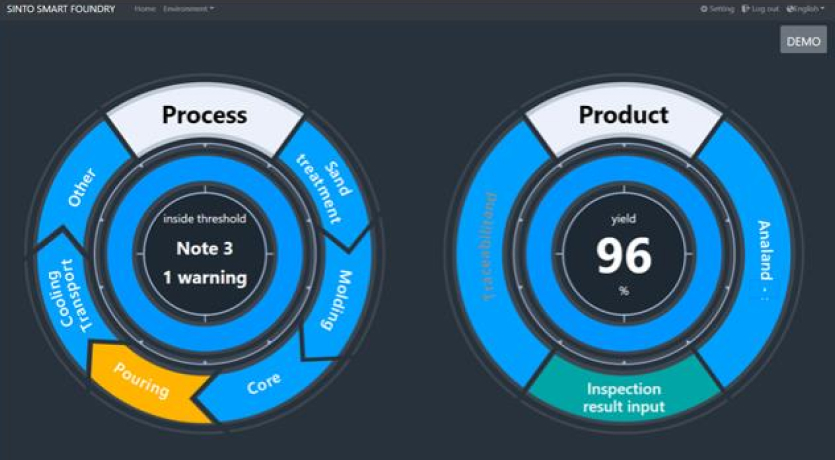

Sand treatment

Molding

Core

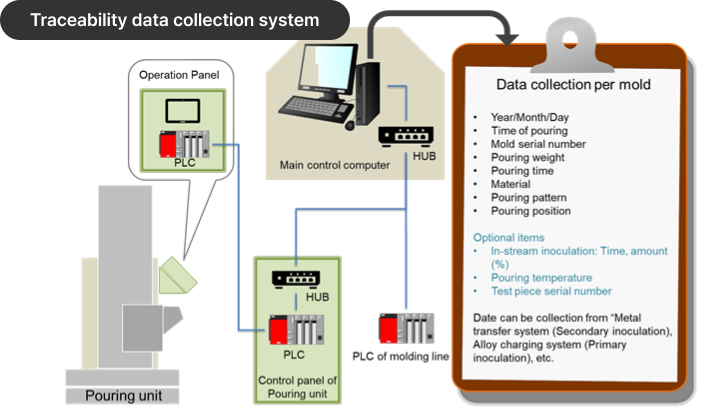

Melting・Pouring

Cooling

After treatment

Judge

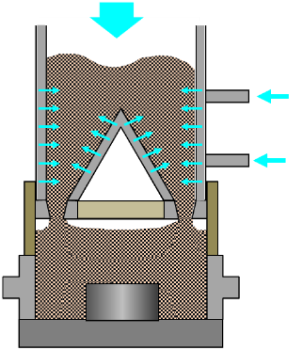

By reducing friction with chamber wall by aeration sand filling method, lower compressed air can be used, achieving uniform sand fill.

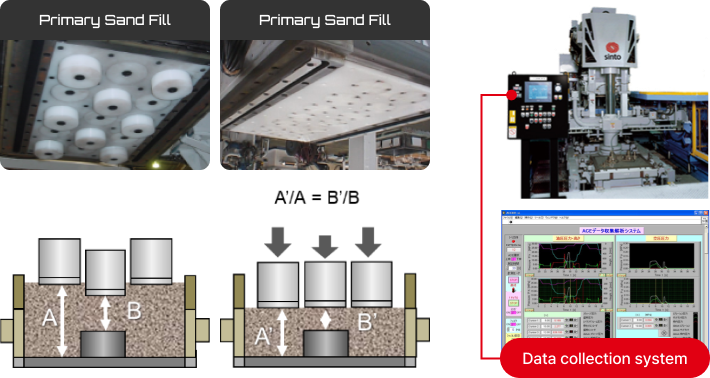

Segment heads are preset according to pattern impression to make overall compression ratio becomes equivalent.

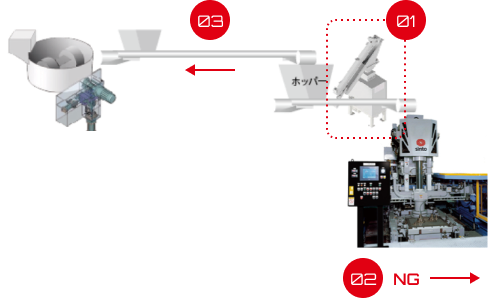

Sand treatment

Molding

Core

Melting・Pouring

Cooling

After treatment

Judge

Sand treatment

Molding

Core

Melting・Pouring

Cooling

After treatment

Judge

Sand treatment

Molding

Core

Melting・Pouring

Cooling

After treatment

Judge

Sand treatment

Molding

Core

Melting・Pouring

Cooling

After treatment

Judge

Sand treatment

Molding

Core

Melting・Pouring

Cooling

After treatment

Judge

HOME

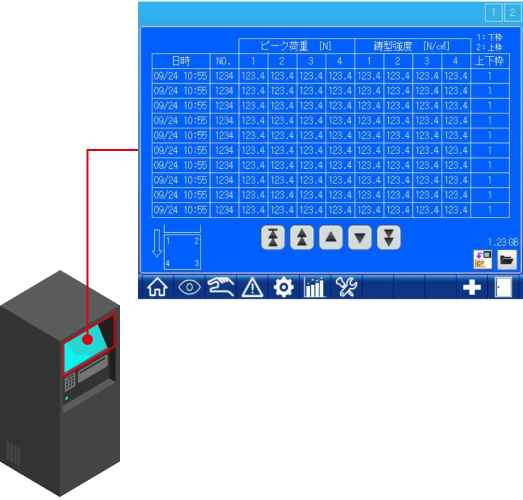

Trend Graph

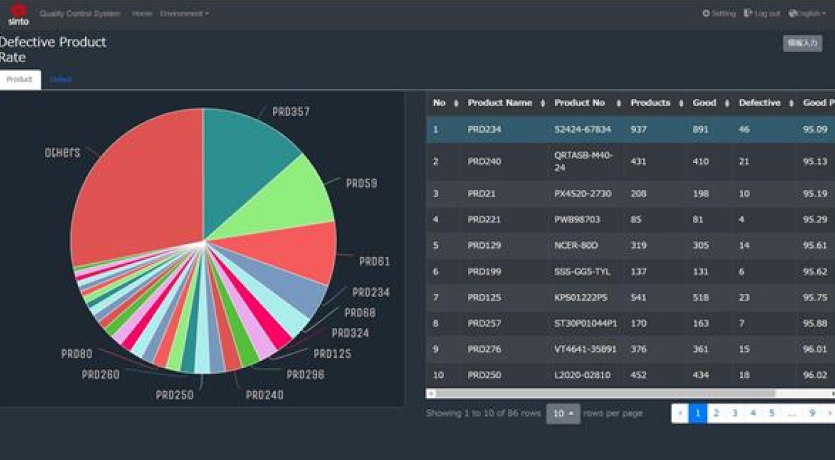

Product defect chart

Sand Quality Display from data by IDST