| Dimensions |

580(W) x 630 (L) x 760 (1100 including screen) (H) (mm)

LCD Panel: 8.4 inches

|

| Weight |

140 kg |

| Utility |

AC100V 15A 50/60Hz |

| Furnace |

Max. temperature 900°C / Initial setting 850°C |

| Dryer |

Heater: Max. temperature 200°C, Set temp. 140°C, Sand temp. 100~140°C |

| Available process |

Alkalic phenol process, Furan process, etc. |

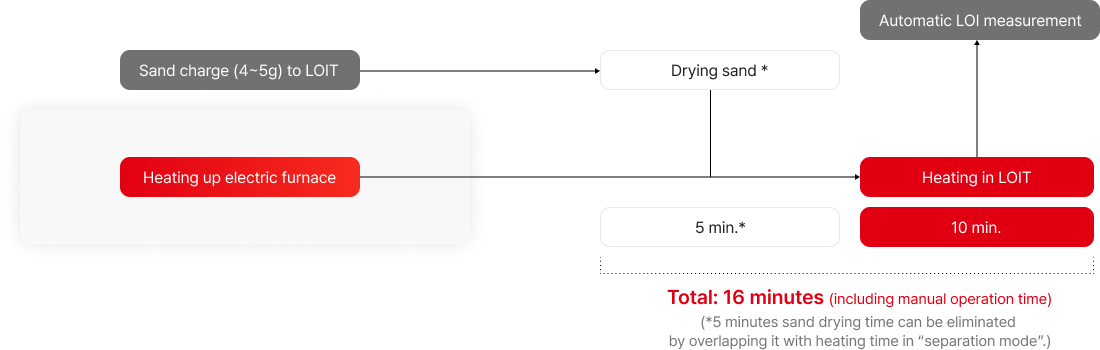

| Measurement mode |

Roasting and drying time are set by timer.

Drying process separation (When it is ON, next sample can be dried during roasting.)

|

| Data output |

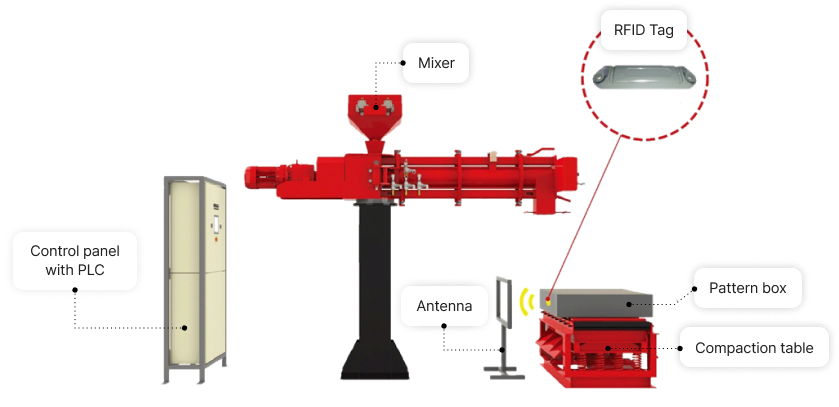

CSV format (via. SD card or USB memory stick) |

| Usage environment |

To be installed on horizontal base or floor, Ambient temperature: 30°C and below, Clearance for 100mm needed around machine |

| Accessories |

(3) Ashtrays for measuring ash content |

| Options |

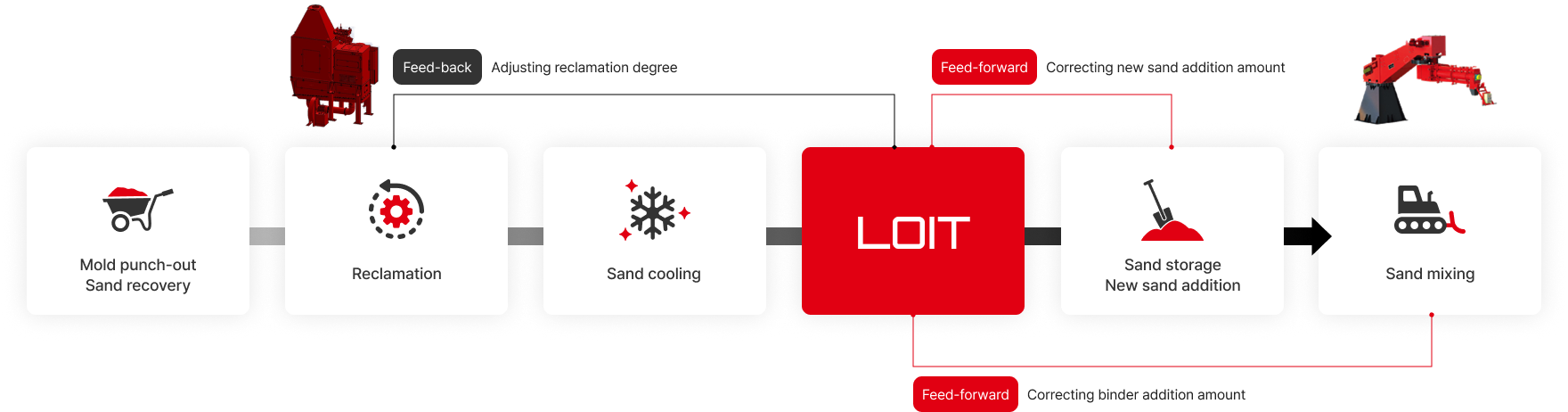

- ① Ethernet (LAN Port): Data can be transmitted to sand reclaimer (USR) to control reclamation degree. (Feed-back function)

- ② Installation base

- ③ Spare ashtrays for measuring ash content

- ④ Measuring spoon

|